Products

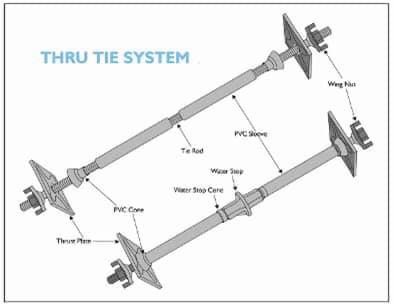

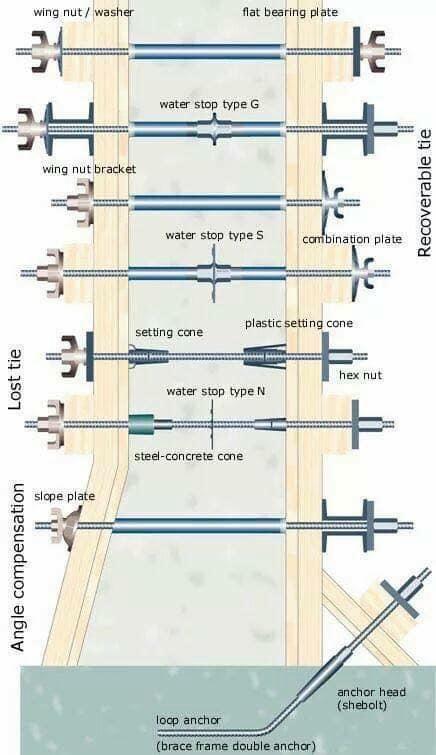

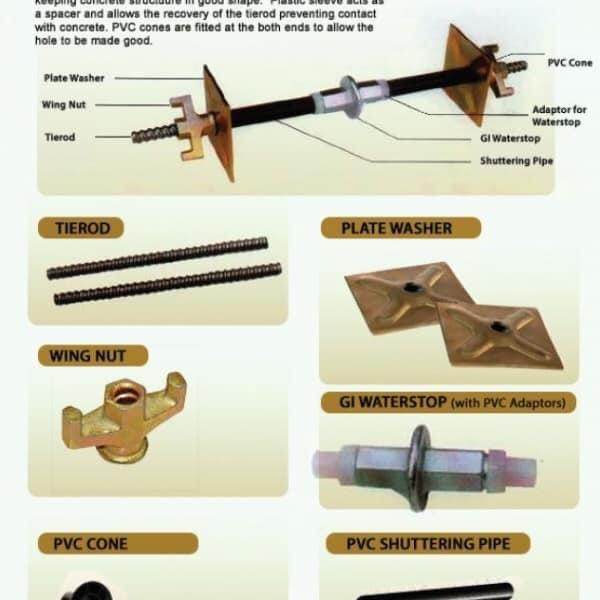

Rod System

A rod system is a system used in various construction and industrial applications to provide support and stability to components or structures using long metal rods (or bars). These rods are installed vertically or horizontally, as needed, to carry or transfer loads or to stabilize temporary and permanent structures.

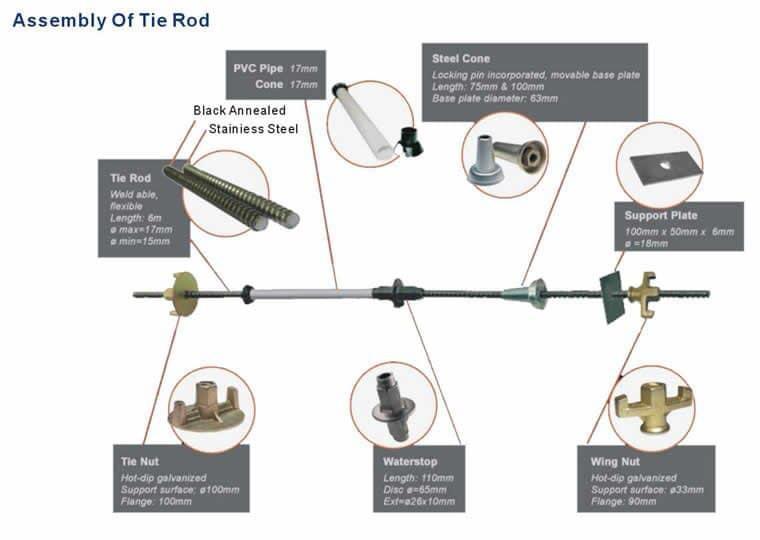

Rod System Components:

Rods: The main component of the system, typically made of strong metal materials such as steel or aluminum to enable them to withstand heavy loads.

Couplers/Joints: These components are used to connect rods together or to connect rods to various points in the structure.

Base Plates/Fixed Plates: These are used to secure rods to surfaces or structures.

Adjustable Ends: Some systems have adjustable ends such as screws or pistons to adjust the length or angle of the rods as needed.

Rod System Features:

Flexibility: It can be used in a variety of applications depending on the type and requirements of the project. Rods can be installed vertically, horizontally, or even at a specific angle.

Durability: This system provides strong support for structures due to the high strength of the rods.

Ease of adjustment: The system can be adjusted in length and angle to meet specific site needs.

Good stability: It enhances the structural stability of scaffolding or structures requiring temporary or permanent support.

Common uses of the Rod System:

Scaffolding systems: Used to provide additional support for scaffolding, whether tubular scaffolding or other scaffolding systems that require additional stabilization.

Structural structures: Used to stabilize and support walls, columns, or concrete surfaces in construction facilities.

Temporary props: Can be used to support temporary structures or formwork during concrete pouring or in projects requiring temporary support.

Industrial projects: Used in factories or workshops where the system requires strong and reliable support.

Arabic

Arabic

.jpg)